Farkhad Ihsan Hariadi

STEI-ITB

Adi Indrayanto

STEI-ITB

Mervin T. Hutabarat

STEI-ITB

Kumara Destantyo

STEI-ITB

Abstract

Automatic Optical Inspection (AOI) is a standard method used in the quality control of electronic board manufacturing processes. Using this method a number of defects can be detected and identified. In this research activities, a number of machine learning methods that can be used for object detection and classification in AOI are first reviewed and evaluated. In this stage of the research a machine learning algorithm based on CNN ( Convolutional Neural Network ) is selected and implemented. For the AOi mechanical platform, a low cost platform which uses 3 motion axis is selected. The platform of the PCBA is driven by two stepper motors for the X and Y axis, respectively. A stepper motor driver module is used to control the motion of each stepper motor.

Keywords: AOI, stepper motor driver, CNN

Introduction

Automated Optical Inspection (AOI) is a critical technology used in electronic board assembly processes to insure high-quality production and early defect detections. There are a number of key purposes of using AOI: (i) Defect Detection: AOI systems use high-resolution cameras and advanced image processing software to visually inspect printed circuit boards (PCBs) for defects such as missing components, misaligned parts, soldering issues, and surface defects, (ii) Quality Control: By identifying defects early in the manufacturing process, AOI helps maintain consistent quality and reduces the risk of defective products reaching the market, (iii) Increased Efficiency: Automated inspection is faster and more reliable than manual inspection, leading to increased productivity and reduced inspection time.

At present, the cost of AOI equipments iis still difficult to afford for small and medium electronic manufacturing industries. It is also significant to note that the present AOI equipments have not implement Artificial Intelligence (AI) or Machine- Learning (MP) in their products. With advanced in the electronic hardware capability and in machine learning methods it is expected that new prototypes AOi with more affordable cost can be realilzed. The objective of thi research project is to develop an early prototype of AOI equipment more affordable for small and medium electronic industries.

Research Method

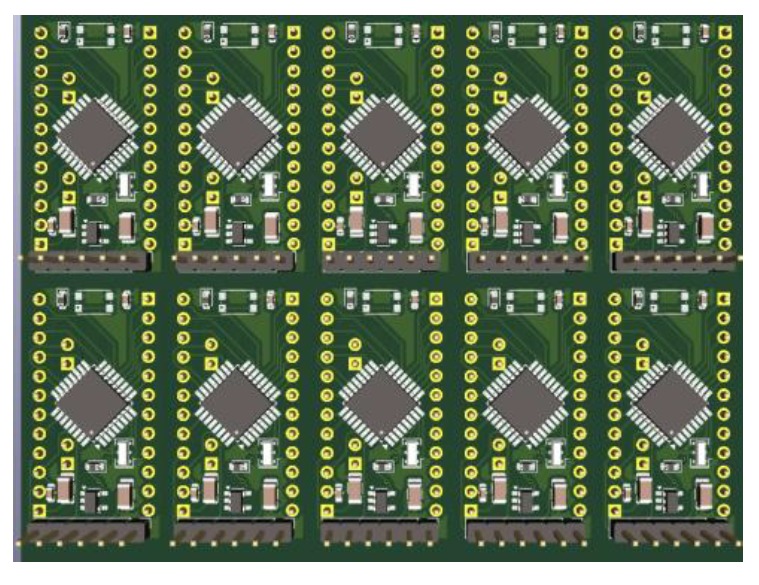

The PCB layout representing the typical PCBA to be checked in this research work is as shown in figure 1 below. This figure shows a PCBA panel of an Arduino Pro-Mini PCBA with the packages of ATmega- 328P as the type of it’s main microcontroller.

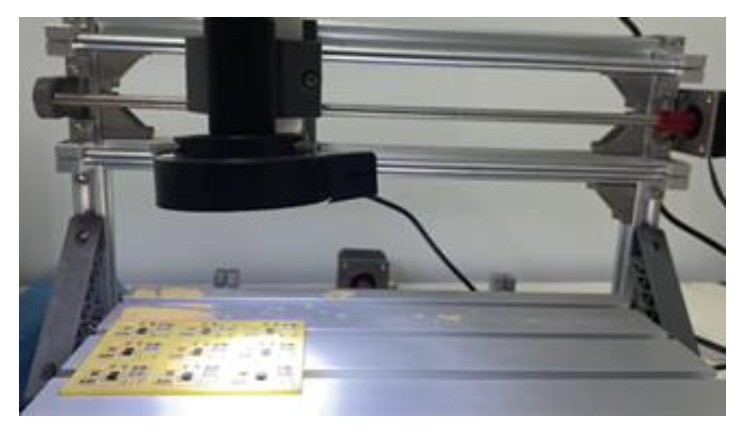

The mechanical platform to be used in this developed prototype is a relatively low cost platform as shown in figure 2 below. This is a ready-to-use mechanical platform intended for small-scale PCB (Printed Circuit Board) rapid prototyping. For our purpose, we have replaced the drilling / milling tool with a CMOS digital microscope camera suitable for imaging small electronics component on a PCBA.

The mechanical platform shown in figure 1 uses screw-driven mechanism as shown in figure 3 for the motion control. this mechanism is expected to provide higher reliability and longer lifetime compared to the types using belt and pulleys. The stepper motors used for the X and Y motions are of 2 phase types.

To detect and classify the errors in the electronic componen placements processes, a machine learning (ML) method using Convolutional Neural Networks (CNN) with general form as shown figure 4 is used. This detection and classification is implemented as a program running on PC.

Discussion & Result

The first processed to be done in AOI evaluation here is to scan the image of the PCBA being evaluated. For this purpose, the microscope camera is moved along both the X and Y axis, respectively. For evaluating the performance of the CNN classification program, the detection and classification process is still performed offline, and is still using generic sample images. Figure 6 below shows example of simple data set showing the example of 2 types of defects, missing components and placement with a wrong angle.

The performance of the CNN program for detection and classification of 3 image classes : normal / correct placement, missing components and wrong placement angle is shown in figure 6.

Conclusion

The results achieved by present research activities indicate that it is possible to develop low-cost AOI equipments more affordable to small-scale industries. The present results are still limited in scope for classification. Further research works for individual component detections are still required.